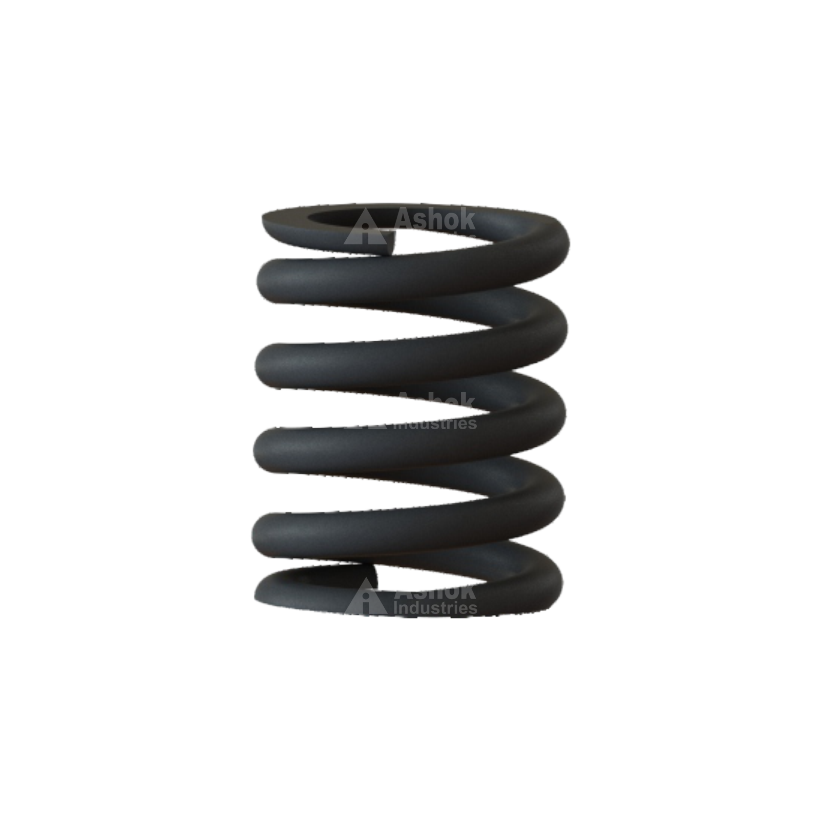

Description

Features and Benefits:

- Impact Absorption: Springs help absorb shocks and impacts, reducing wear on equipment and enhancing operational stability.

- Force Maintenance: Provides consistent force or tension, ensuring reliable performance of machinery and tools.

- Durability: Built from high-strength materials, Springs are designed to withstand harsh conditions, ensuring long-lasting performance in demanding environments.

- Enhanced Equipment Life: By reducing friction and impact, Springs contribute to extending the lifespan of drilling and construction tools.

- Versatile Applications: Can be used in various systems, including locking mechanisms, shock absorbers, and coupling devices.

Applications:

- Locking Mechanisms: Springs are used to maintain pressure or force within locking mechanisms, ensuring secure connections.

- Shock Absorption: Essential for absorbing impacts in drilling rigs and other construction machinery, improving safety and reducing downtime.

- Coupling Systems: Used in couplings to maintain force and alignment between connected parts, ensuring smooth operation of tools and machinery.

- Drilling Equipment: Springs are commonly used in drilling rigs, piling machines, and other heavy-duty equipment to ensure proper alignment and reduce the risk of equipment failure.

Ashok Industries Springs are integral components in drilling and construction equipment, providing tension, cushioning, and impact absorption. Their durability, versatility, and ability to maintain force make them essential for maintaining the smooth operation and longevity of machinery. By optimizing performance and reducing wear, Springs contribute significantly to the efficiency and safety of drilling and construction operations.